Table of Contents

Updated: 9/8/2021

Unsafe forklift operations are one of the biggest safety hazards in warehouses. Every year, forklifts are involved in 11% of accidents and are responsible for 100,000 injuries worldwide according to OSHA Safety Management. Whether due to improper training or lack of maintenance, forklifts can cause damage, injury, or even death when used improperly. That’s why regular maintenance and operational checks of forklifts are extremely important. Occupational Safety and Health Administration (OSHA) requires that forklifts be inspected daily. In order to create a safe warehouse, make sure you look for these issues when conducting a pre-operational inspection:

Download or Print Our Sample Checklist

Why Your Operation Should Use Daily Checklists

Safety checklists may seem like repetitive or even unnecessary actions; however, using them not only helps the safety of your employees, but they also positively influence the overall function of your warehouse itself.

Guide Procedure Expectations

There are a variety of general checklists that are offered to companies to ensure warehouse safety. OSHA provides safety checklists that correspond to laws and regulations that help keep employees working in their workspace safe. Following the checklists that they offer will help guide your warehouse’s general safety. These checklists also assess employees to ensure they are properly handling materials and equipment and following procedures set by the warehouse.

Reduce Potential Injuries from Equipment

Following equipment specific checklists for machinery such as forklifts can help avoid potential safety concerns. Operating forklifts pose numerous hazards and daily checklists make sure forklifts are functioning properly to help prevent issues or injuries. This is an important and essential step to reduce dangerous situations for your employees.

Customized Environment Protocols

By creating your own company specific checklists, you are helping to ensure the safety of your operation and employees. Tailoring checklists to your own work environment, such as a warehouse, ensures nothing was missed by a generalized list. By including employees in the process, discussion and feedback can result in even stronger safety protocols. Evaluating safety checklists periodically helps to cover all areas, making sure nothing is left unsafe.

Daily Forklift Pre-Operation Checklist

So you know you need one, but not sure what key items your forklift daily checklist should include? We are here to help. In order to create a safe warehouse, make sure you look for these issues when conducting a pre-operational inspection:

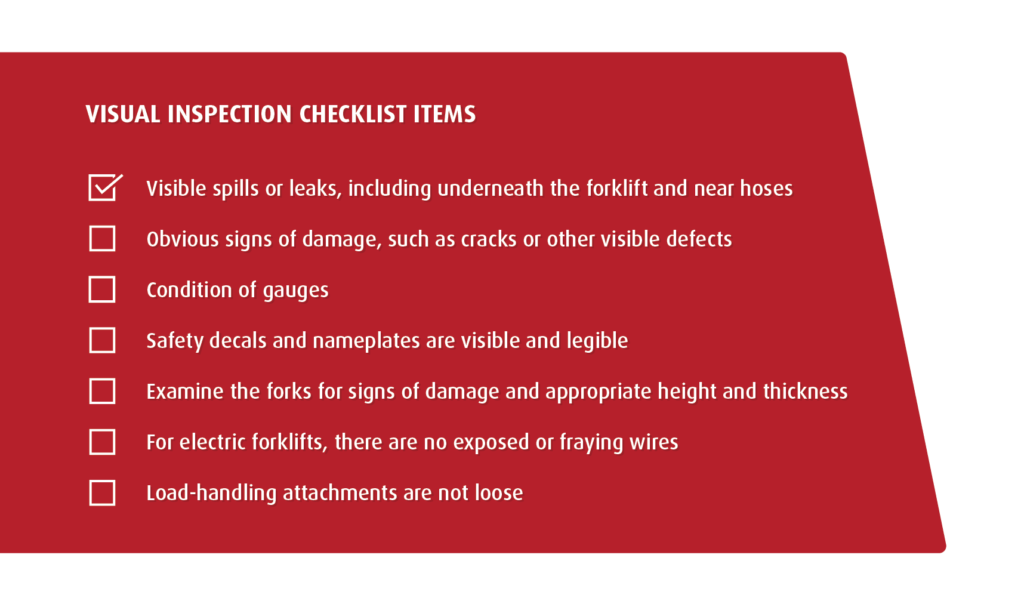

Visual Inspection Checklist Items

Carefully look over the entire forklift for any cracks, leaks, or defects. This includes, but is not limited to, the overhead guard, lift chains and rollers, forks, mast assembly, and hydraulic cylinders. If anything seems amiss, call someone to repair it. Ignoring a leak or possible damage and operating the forklift isn’t worth the risk of injury to an employee.

- Visible spills or leaks, including underneath the forklift and near hoses

- Obvious signs of damage, such as cracks or other visible defects

- Condition of gauges

- Safety decals and nameplates are visible and legible

- Examine the forks for signs of damage and appropriate height and thickness

- For electric forklifts, there are no exposed or fraying wires

- Load-handling attachments are not loose

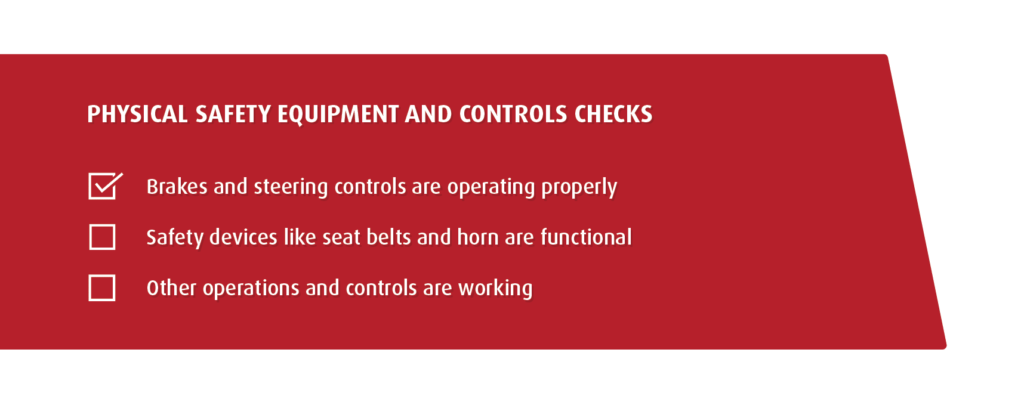

Physical Safety Equipment and Controls Checks

Any problems with the safety equipment could put the lives of your employees at risk. Seatbelts should fasten securely and be free of any tears or fraying. You’ll also want to test the brakes, steering, horn, and front, tail, and brake lights.

- Brakes and steering controls are operating properly

- Safety devices like seat belts and horn are functional

- Other operations and controls are working

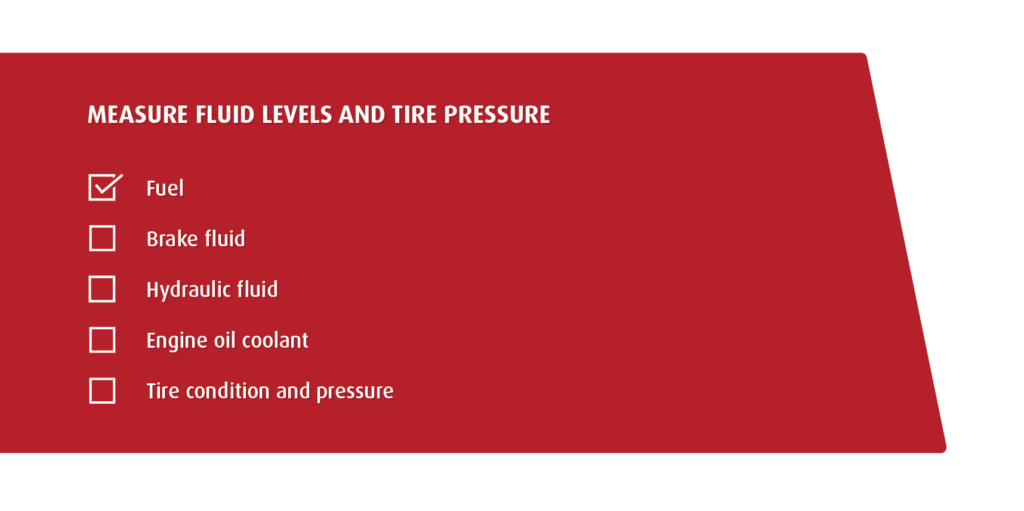

Measure Fluid Levels and Tire Pressure

It is important to ensure that forklifts have enough battery fluid, water, and hydraulic fluid to operate safely at all times. When forklifts are driven in an industrial environment, there is also a risk of punctured tires. Since daily wear and tear can cause tires to deflate, measure the tire pressure and watch out for any slashes or nails.

- Fuel

- Brake fluid

- Hydraulic fluid

- Engine oil coolant

- Tire condition and pressure

Employee Safety

- Check Protective Gear: Although the specific standards for safety equipment may vary slightly depending on employer, protective hard hats, glasses, and reflective clothing will likely be part of the uniform. You should always refer to the official employee dress code since safety equipment such as face shields or gloves may also be part of the requirements.

- Encourage Reference to Safety Guides: The safety guidebook for forklift use and the operator’s manual should always be accessible to employees. Managers should also be available to answer any questions regarding safety. Make sure that employees are up-to-date on the latest forklift technology and safety requirements. Altough certification programs are available online for forklift operation, managers should also include a job-specific safety course for all new and existing employees.

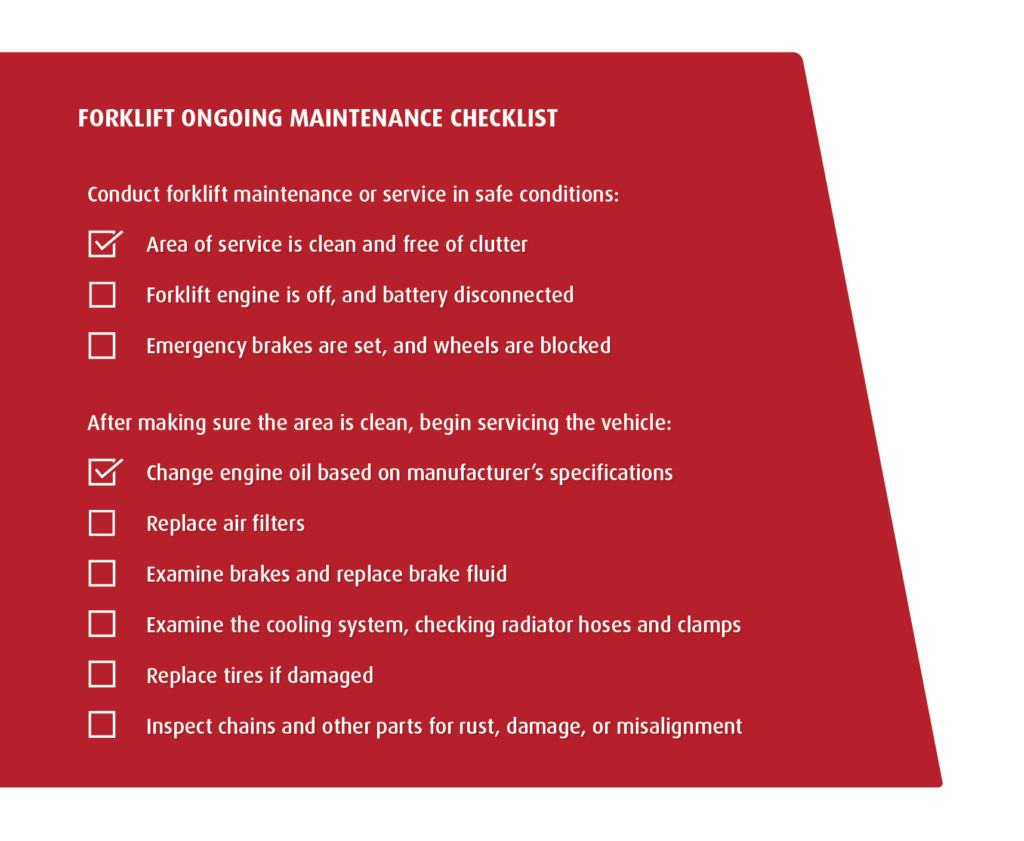

Forklift Ongoing Maintenance Checklist

In addition to pre-operational checks, forklifts should undergo further inspection and maintenance based on days, months, or hours of operation. The following are the best practices for conducting more comprehensive maintenance checks:

Conduct forklift maintenance or service in safe conditions:

- Area of service is clean and free of clutter

- Forklift engine is off, and battery disconnected

- Emergency brakes are set, and wheels are blocked

After making sure the area is clean, begin servicing the vehicle:

- Change engine oil based on manufacturer’s specifications

- Replace air filters

- Examine brakes and replace brake fluid

- Examine the cooling system, checking radiator hoses and clamps

- Replace tires if damaged

- Inspect chains and other parts for rust, damage, or misalignment

Linde Material Handling Forklift Inspections and Equipment Quotes

Linde Material Handling is trusted worldwide and prides itself on offering specific solutions for your organization to help you take your business to the next level. Those solutions include tips and strategies to ensure your operation is functioning at peak performance and that your operators have the tools they need to succeed.

This checklist is just a starting point for conducting appropriate forklift maintenance inspections. For more information on inspecting a Linde Material Handling lift truck or to get a quote contact us.