What comes to mind when you think about the word safety? Is it focusing on preventative measures, staying alert, or avoiding certain situations? Safety can mean so many different things to each of us; each approach can also be different depending on the situation.

When referencing forklift safety, there are typically a few primary focuses – the forklift truck, operator, and pedestrians. For many in the industry, the first thoughts that probably come to mind running a safe operation might include:

- Consistent signage and early warnings

- Pedestrian right of ways

- Regular internal safety meetings and those regulated by OSHA

- Maintaining low speeds

- Clear internal communication signals for pedestrians and operators

- Properly maintained forklift trucks

If you thought of any of these ideas beforehand, you are on the right track to managing a safe operation. But what if training and relying on all your employees to comply with those measures isn’t enough?

Our post-pandemic world has caused a significant shift and strain on many of our businesses. And with the rise of supply chain challenges and the dramatic increase in employee turnover, these shifting dynamics can lead to safety challenges. Your organization may have thought of every possible risk or hazard an operator or pedestrian can encounter, but if those individuals are here today and gone tomorrow, how will you ensure the topic of safety penetrates your organization? As business owners, leaders, and managers, we must ensure safety becomes a part of our culture – starting from the top down. But along with that, we can also leverage technology that can support secure and productive operations. Those tools include deploying automated guided vehicles, collision avoidance systems on manually operated trucks, and telematics.

Automated Guided Vehicles (AGFs)

Automated guided vehicles help create consistency in an operation that assists in supporting safety. The AGVs offer speed control, obstacle detection, and interfacing with warehouse management systems. These tools help create purpose-driven designs by operating the fleet more effectively and improving safety. Click here to learn about Linde Automated Solutions customizable to your operation and needs.

Linde Guardian

The Linde Guardian system assists all personnel involved in internal traffic and extends an additional level of protection for pedestrians and forklift operators. Policies and procedures for safety within your business are imperative; however, even implementing the best plans for avoiding hazards, mistakes and accidents will happen. Linde Guardian enables automatic capabilities, including seeing around corners and through walls, providing automatic speed reductions, and being programmed to suit any hazardous scenario. This deployable technology can be installed on forklift trucks, buildings, and pedestrians, creating a holistic confidence level for your business. Find out more on the benefits of Linde Guardian here.

Telematics

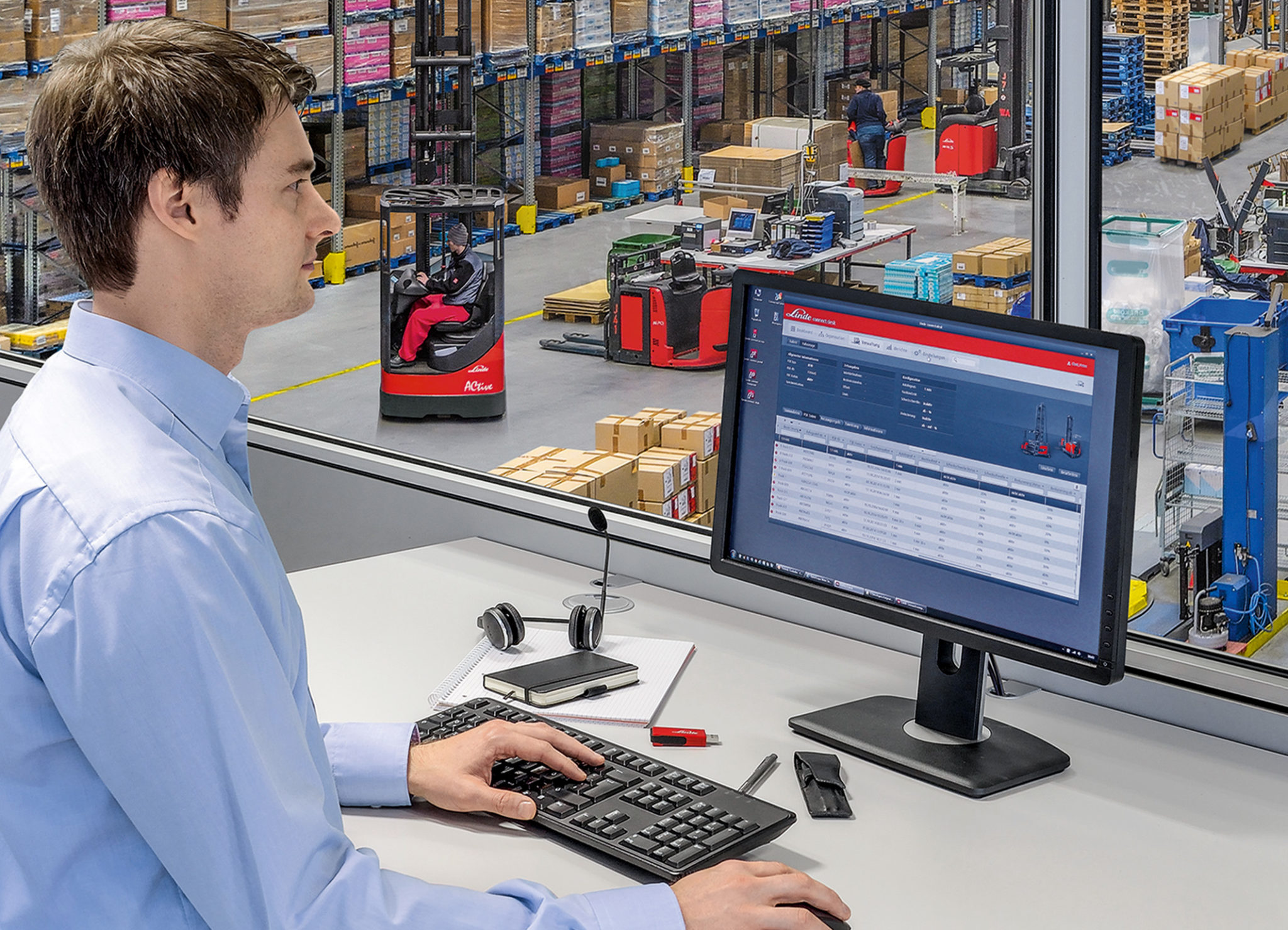

Telematics influences safety by utilizing pre-operational checklists to ensure vehicles are operational and to identify those trucks unfit for use, including lockouts. This tracking system determines which trucks need repair before launching back in service. In addition, in combination with Linde Guardian, zone and speed control can be tied back to training records within the system. Collecting critical information on your assets can help you better plan truck maintenance and repairs while ensuring your operators use safe and reliable equipment.

The ever-changing business landscape of increased demand for products and tight deadlines puts an increased strain on conducting safe operations. That fact makes it essential that operations look at additional options for safe operations.

By leveraging technology, your business has a greater opportunity to support safe, profitable, and productive operations.